Siffofin

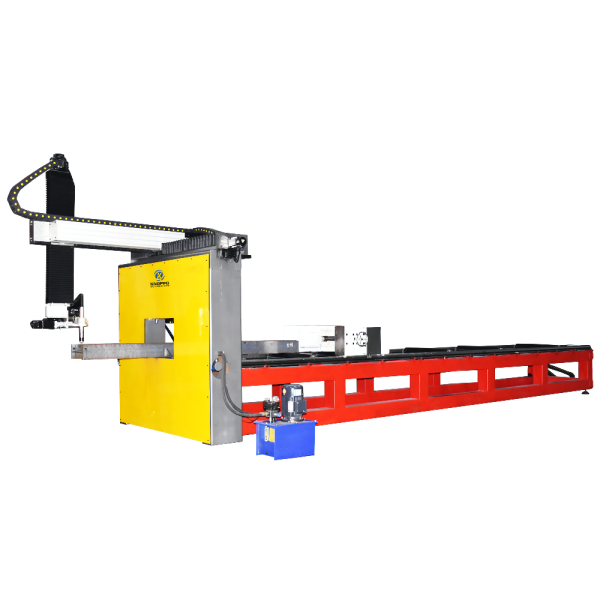

Ba kamar inji inda workpiece ke juya ba, yana buƙatar nemo cibiyar.Wannan inji na iya nemo cibiyar ta atomatik ba tare da gano cibiyar da hannu ba.Ana ɗaga kayan aikin sama kuma ana tura silinda ta atomatik don fara yankan.

Yin amfani da shirye-shiryen ɗakin karatu, ana iya samar da hanyar yanke ta hanyar shigar da girman da nisa dangane da wurin farawa bisa ga zane-zane a cikin ɗakin karatu, ba tare da wani tushe na shirye-shirye da zane ba, kowane matashi mai hankali zai iya sarrafa yanayin aiki a cikin kawai 'yan sa'o'i kadan.

GABATARWA LABARI

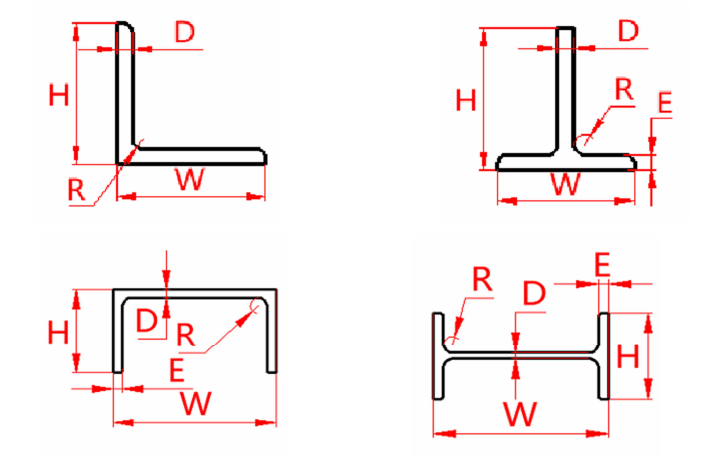

1. Tallafi nau'ikan nau'ikan karfe huɗu na sashe

2.Basic graphics

Za a iya shigar da zane-zanen da ke cikin wannan kasida a cikin girman da daidaitawa a kan tsarin tsarin, ta yadda za a iya yanke su a kowane matsayi a kan kowane farfajiya na sassan giciye hudu na sama.

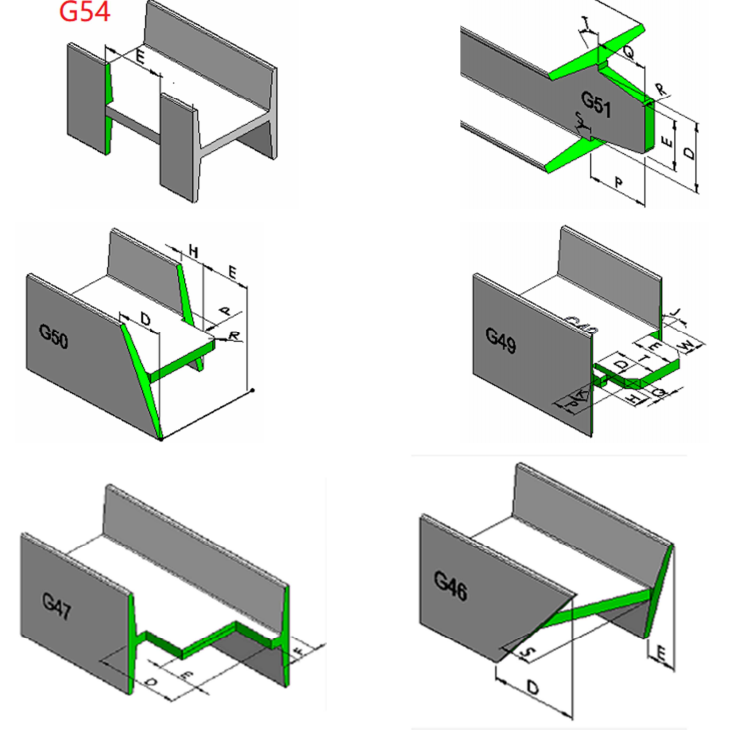

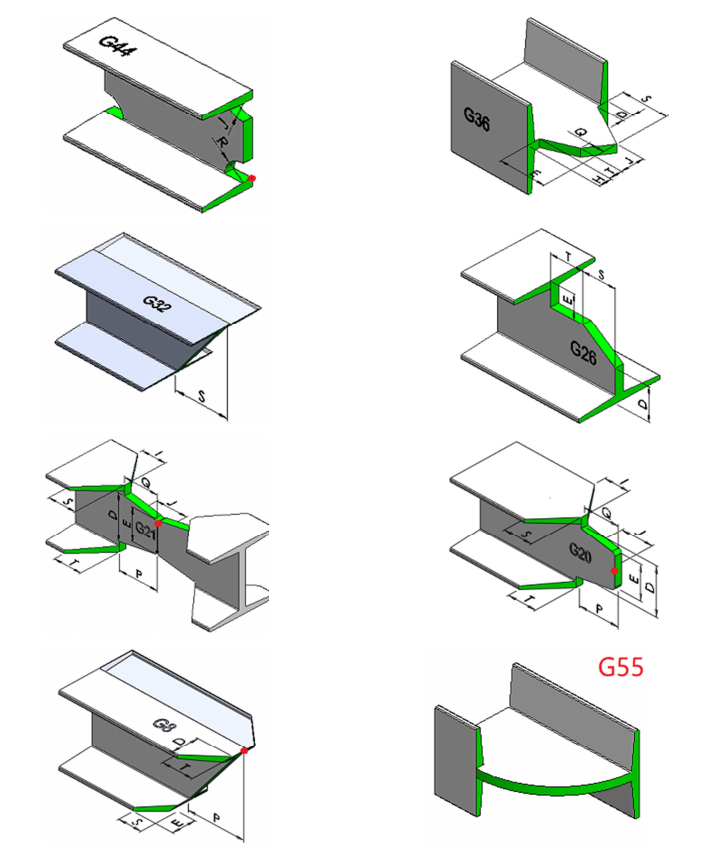

3. Dedicated graphics

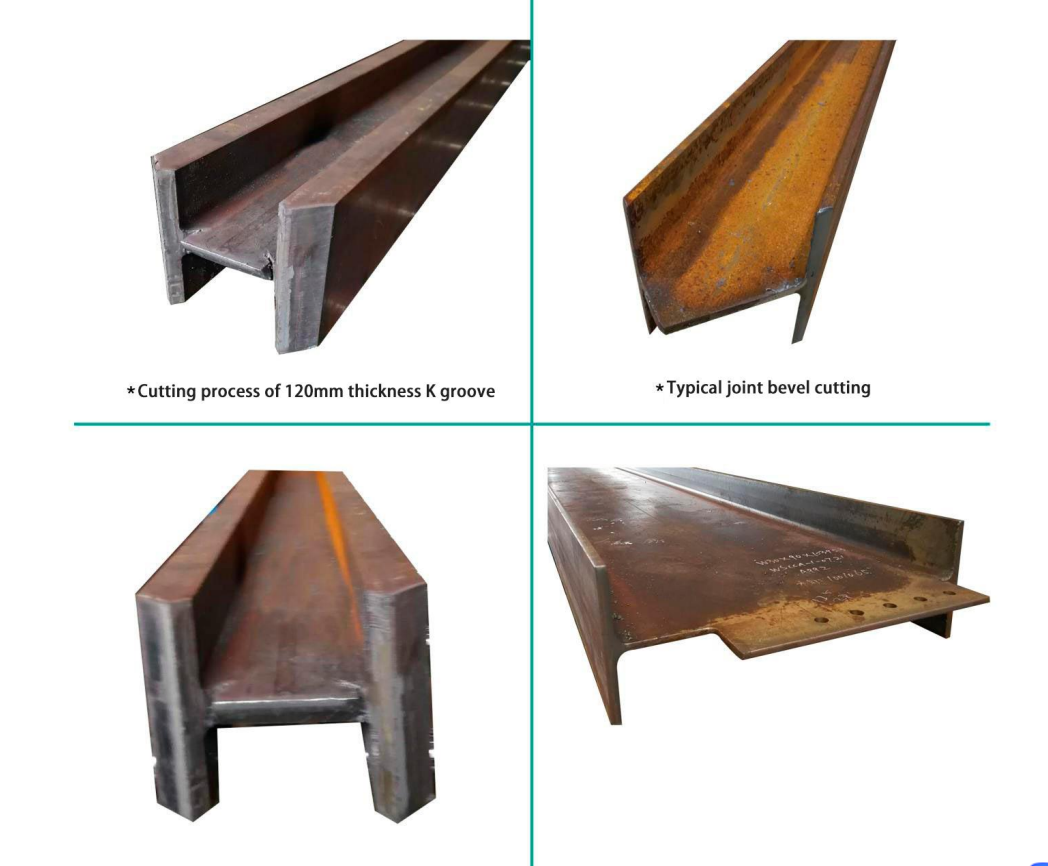

Ana amfani da shi don yanke wani nau'i na karfe, irin su guntu, makullin layi, da dai sauransu. Za'a iya yanke zane-zane masu zuwa ta hanyar shigar da girman da matsayi a kan mahaɗin.

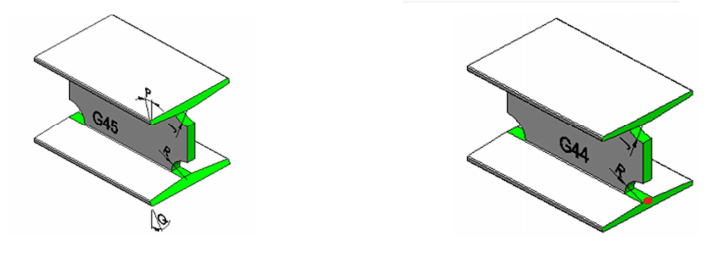

H-beam sashi:

Ma'aunin Fasaha

| Samfura | T300 |

| Ƙarfin Plasma | 200A |

| Yankan Diamita | 800*400mm |

| Tsawon Yanke | 6m / 12m |

| Direba | Japan Fuji Servo Motor |

| Nau'in Motsi | 6 Axis |

| Tsari | Shanghai Fangling |

| Beveling | Ee |