Aikace-aikace

Application Of Fiber Laser Cleaning Machine

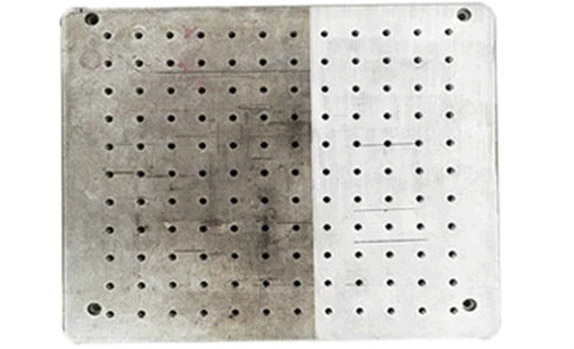

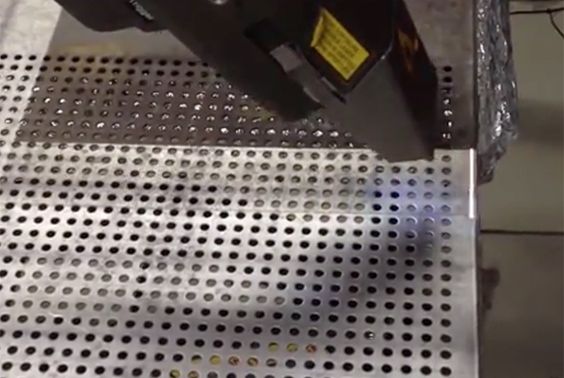

1. Mold masana'antu

Laser na iya yin tsaftacewa ba tare da tuntuɓar ƙirar ba, wanda ke da aminci sosai ga saman ƙirar, zai iya tabbatar da daidaitonsa, kuma yana iya tsaftace ƙwayoyin datti na sub-micron waɗanda ba za a iya cire su ta hanyoyin tsabtace gargajiya ba, don haka cimma ainihin ƙazantacce, inganci da tsaftacewa mai inganci.

2. Madaidaicin kayan aiki masana'antu

Madaidaicin masana'antar injuna sau da yawa yana buƙatar cire esters da man ma'adinai da ake amfani da su don lubrication da juriya na lalata daga sassa, yawanci ta hanyar sinadarai, kuma tsabtace sinadarai galibi suna barin ragowar.Ƙwararren Laser na iya cire esters gaba ɗaya da mai na ma'adinai ba tare da lalata saman sassan ba.Laser yana inganta iskar gas mai fashewa na bakin ciki na oxide Layer a saman sashin don samar da girgizar girgiza, wanda ke haifar da kawar da gurɓataccen abu maimakon hulɗar inji.

3. Masana'antar dogo

A halin yanzu, duk pre-welding tsaftacewa na dogo rungumi dabi'ar nika dabaran da abrasive bel nika nau'in tsaftacewa, wanda ya haifar da mummunan lalacewa ga substrate da kuma tsanani saura danniya, da kuma cinye mai yawa nika dabaran consumables a kowace shekara, wanda shi ne m da kuma haifar da tsanani. gurbacewar kura ga muhalli.Tsaftace Laser na iya samar da ingantacciyar fasahar tsabtace kore mai inganci don samar da hanyar dogo mai sauri ta ƙasata, magance matsalolin da ke sama, kawar da lahani na walda kamar ramukan dogo maras sumul da launin toka, da haɓaka kwanciyar hankali da amincin babban ƙasata. -gudun aikin layin dogo.

4. Masana'antar sufurin jiragen sama

Ana buƙatar gyara saman jirgin bayan wani ɗan lokaci, amma ainihin tsohon fenti yana buƙatar cire gaba ɗaya kafin zanen.Yin nutsewa/shafe sinadarai shine babban hanyar cire fenti a filin jirgin sama.Wannan hanya tana haifar da babban adadin sharar kayan taimako na sinadarai, kuma ba shi yiwuwa a cimma gyare-gyaren gida da cire fenti.Wannan tsari yana da nauyin aiki mai nauyi kuma yana cutar da lafiya.Tsaftace Laser yana ba da damar cire fenti mai inganci a saman fatun jirgin sama kuma ana iya sarrafa shi cikin sauƙi don samarwa.A halin yanzu, an yi amfani da wannan fasaha don kula da wasu samfurori masu daraja a ƙasashen waje.

5. Masana'antar kera jiragen ruwa

A halin yanzu, tsaftacewar jiragen ruwa da ake samarwa kafin samarwa, galibi sun ɗauki hanyar fashewar yashi.Hanyar fashewar yashi ya haifar da mummunar gurɓatar ƙura ga muhallin da ke kewaye kuma an dakatar da shi a hankali, wanda ya haifar da raguwa ko ma dakatar da samarwa daga masana'antun jiragen ruwa.Fasahar tsaftace Laser za ta samar da maganin tsabtace kore da ƙazanta mara ƙazanta don feshin lalata a saman jirgi.

Misali

Siffofin fasaha

| NO | Bayani | Siga |

| 1 | Samfura | KC-M |

| 2 | Ƙarfin Laser | 1000W 1500W 2000W |

| 3 | Nau'in Laser | MAX / Raycus |

| 4 | Tsawon zangon tsakiya | 1064nm ku |

| 5 | Tsawon layi | 10 M |

| 6 | Tsaftacewa inganci | 12m3/h |

| 7 | Harshen tallafi | Ingilishi, Sinanci, Jafananci, Koriya, Rashanci, Sifen |

| 8 | Nau'in Sanyi | Ruwa sanyaya |

| 9 | Matsakaicin Ƙarfi (W), Max | 1000W / 1500W/ 2000W |

| 10 | Matsakaicin Ƙarfin (W), Rage fitarwa (Idan an daidaita shi) | 0-100 |

| 11 | Mitar bugun jini (KHz), Range | 20-200 |

| 12 | Nisa Ana dubawa (mm) | 10-150 |

| 13 | Nisan Hankali da ake tsammani (mm) | mm 160 |

| 14 | Ƙarfin shigarwa | 380V/220V, 50/60H |

| 15 | Girma | 1100mm × 700mm × 1150mm |

| 16 | Nauyi | 270KG |